Anping Molonggang Spot Welding Equipment Company Limited, founded in 1990 located in Anping County--the biggest hometown of

wire mesh in China. Molonggang is a professional comprehensive

enterprise integrating manufacture, marketing, and exporting and

importing trade of wire mesh products.

We are a professional factory that manufactures all kinds of wire

mesh machines. With having first- class wire mesh machines,

scientific technology and quality inspection system to ensure the

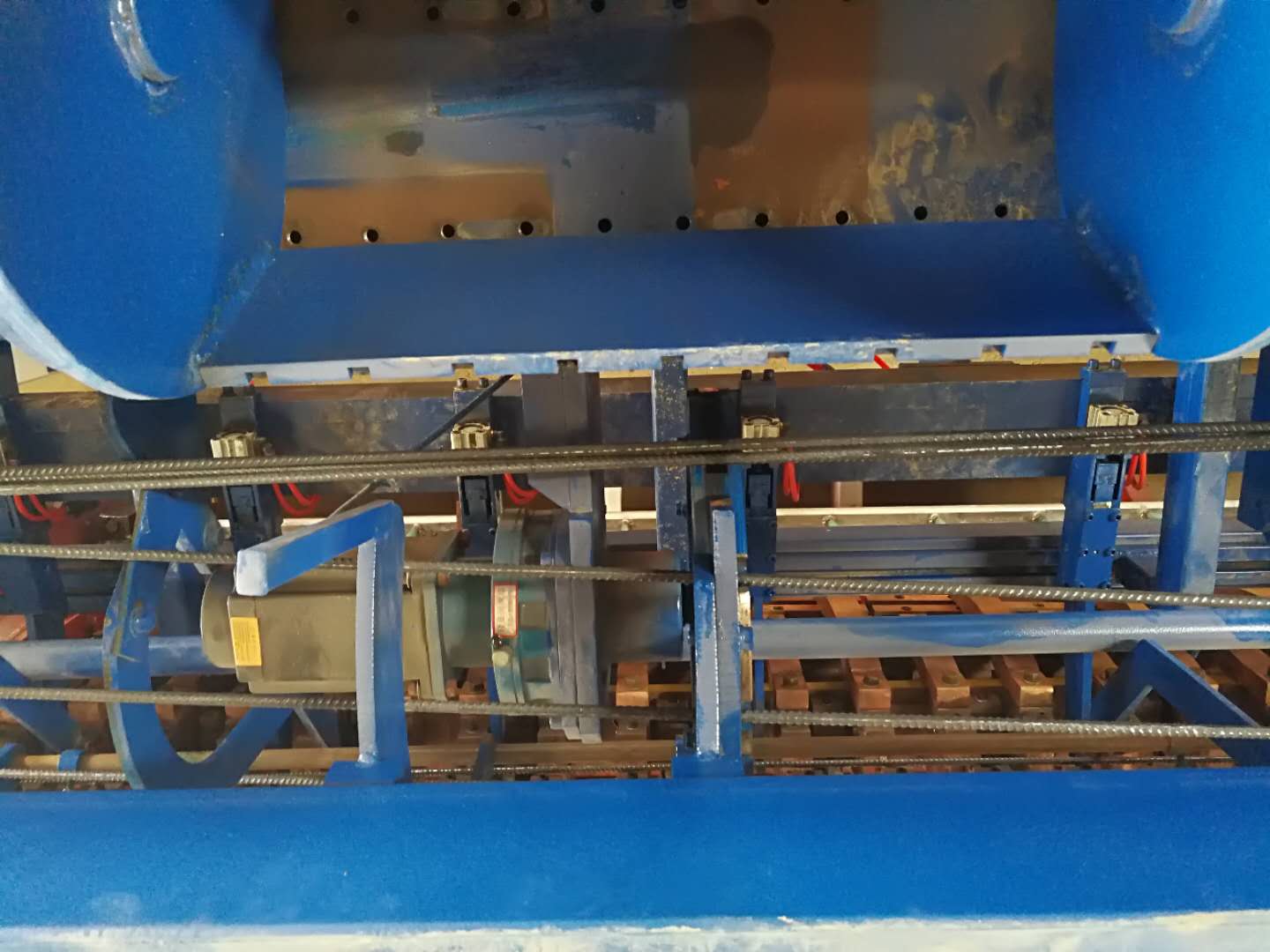

quality of our wire mesh products. We manufacture for: Automatic welded mesh welding machine, automatic

concrete reinforcing mesh welding machine, full automatic chain

link fence machine, full automatic welded wire mesh machine,

hexagonal wire netting machine. Expanded metal mesh machine, field

fence machine and so on. We can manufacture complete product design, part

working and machine assemble, strong technical strengthen and

immediate service can meet customer’s need.

Automatic welded mesh welding machine

Automatic concrete reinforcing mesh welding machine

Full automatic welded wire mesh machine

Full automatic chain link fence machine

Our factory seeks existence by quality and development by reputation. We have more than 10 researchers with high skills; the product by

our machine has various kinds and high quality. We can manufacture

different specifications according to the clients’ demand. So far,

we have established long-term business relationship with Russian,

Iran, Vietnam,Jordan, Saudi Arabia,Oman, Nigeria,

Indonesia,Philippines and other countries and areas. Get a high

reputation.

We pay attention to communicating with customers actively. To get

to know the customers’ demand and offer excellent service, we

sincerely expect to establish friendly business relationship with

the customers from all over the world.