Automatic concrete reinforcing mesh spot welding machine

1. The machine is used for wire diameter 5-12mm, it is an automatic

equipment that desiged and manufactured by ourselves. Both the line wire and cross wire are feed from pre-cut wire, the

controlling system adopts PLC control; the machine adopts servo

motor to pull the mesh panel repeat.

2. The machine uses PLC touch screen control technique, we use Japan, Sony digital control system which can be input to

touch screen control panel to adjust the mesh size, so it can weld

different mesh size on the same mesh panel .

3. Water-cooling transformer and water-cooling lower electrodes to make sure the welding firm during a long working time, and

prolong the service life.

4. Feeding and Welding System Cross wire feeding: Firstly, the coil wires are straighten and cut into fixed length

by straightening cutting machine, which become weft wire. Then

worker put the weft wires into wire hopper. Wire hopper under the

control of air pump, the cross wires falling automatically one by

one.

Line wire feeding: warp wires are the same to weft wires, firstly use straightening

cutting machine to straighten and cut coil wire into fixed length. Then the line wires are sent by labor and fed automatically, when

it welding and drawing, labors can prepare the wires, it increases

production efficiency.

5. Welding system: the machine adopts synchronous and PLC control technique. The

welding power comes from the spring. At the same time, the welding

electrodes are equipped with water cooling system to make sure the

welding during a long working time, and prolong the life .

6. The mesh pulling system is controlled by servo motor, which makes the pulling mesh

aperture more standard and accurate.

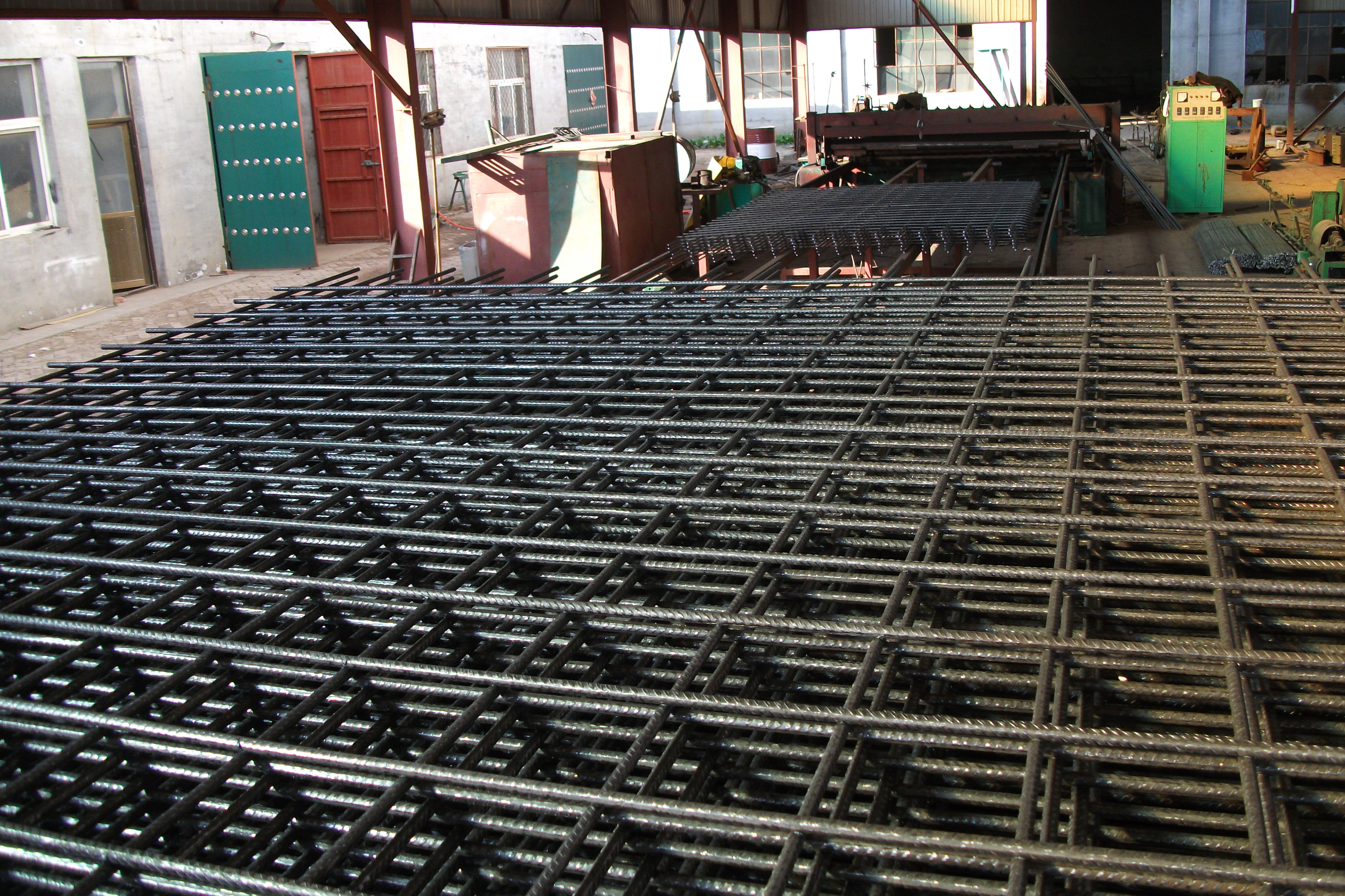

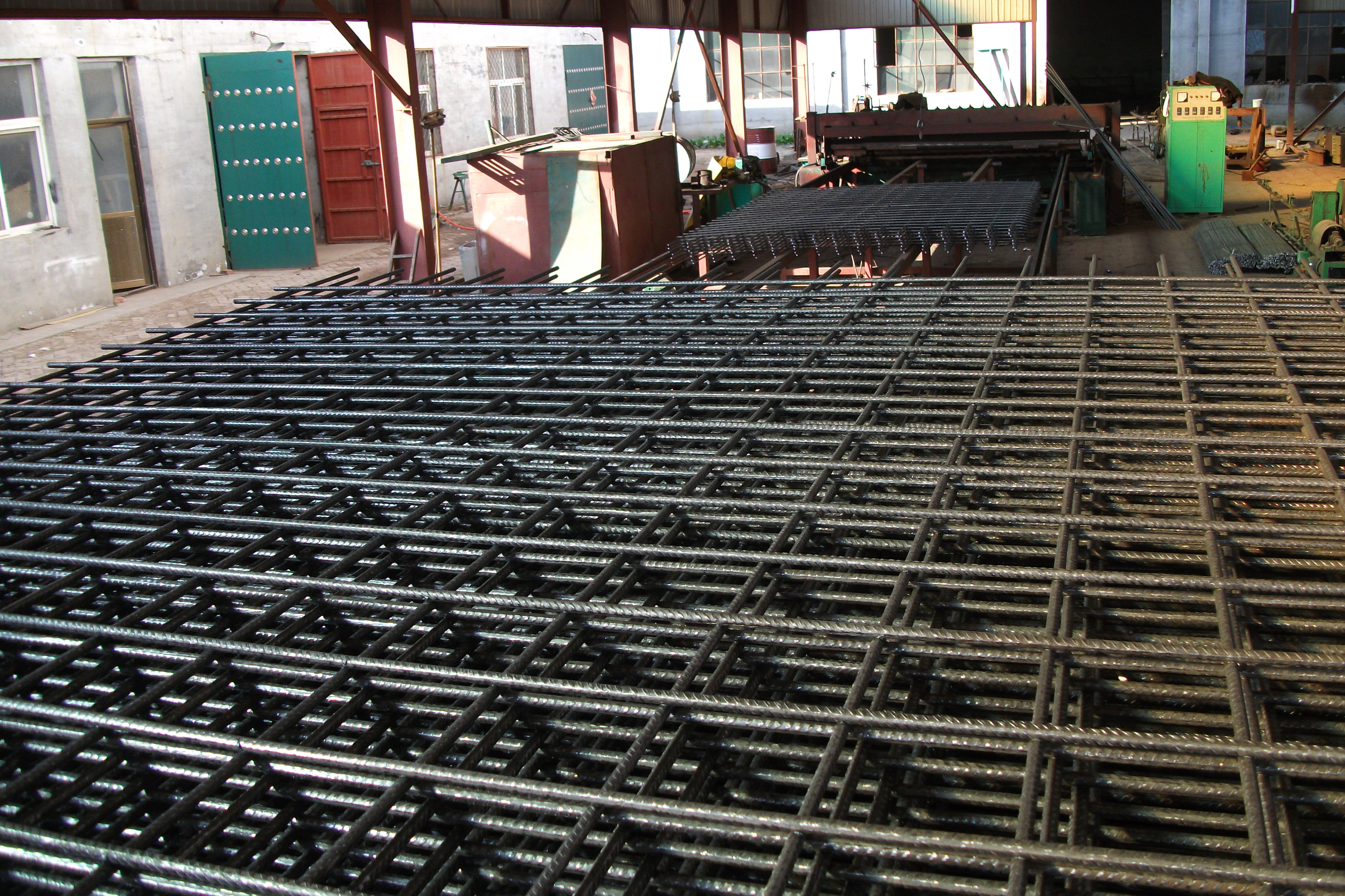

7. Mesh falling system: Automatic falling mesh panel system is adopted, so it save much

labor to move the mesh panels.

The Main Parameters

| Items | DC-12MA-50-1200 | DC-12MA50-1600 | DC-12MA50-2500 |

| wire diameter | 5-12mm | 5-12mm | 5-12mm |

| line wire space | 100-300mm | 100-300mm | 100-300mm |

| cross wire space | 50-300mm | 50-300mm | 50-300mm |

| wire forms | pre-cut wires | pre-cut wires | pre-cut wires |

| mesh width | 1200mm | 1600mm | 2500mm |

| number of electrodes | 12 (customzied) | 16(customized) | 25(customized) |

| welding speed | 40-60times/min | 40-60times/min | 40-60times/min |

| Cooling system | Water cooling transformer | Water cooling transformer | Water cooling transformer |

| Controlling system | PLC touch screen | PLC touch screen | PLC touch screen |

All the parameters can be customzied according to customers'

requirement.